Detailseite für das News-Plug-In auf der Startseite

New publication in Sci

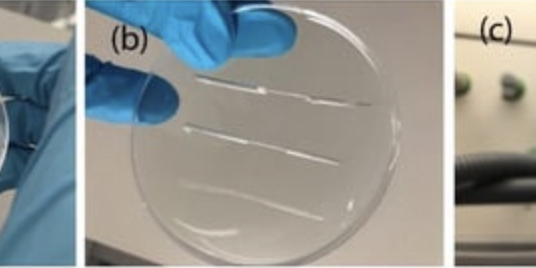

The common method for producing casting molds for the fabrication of polydimethylsiloxane (PDMS) chips is standard photolithography. This technique offers high resolution from hundreds of nanometers to a few micrometers. However, this mold fabrication method is costly, time-consuming, and might require clean room facilities. Additionally, there is a need for non-micromechanics experts, who do not have specialized equipment to easily and quickly prototype chips themselves. Simple, so-called, makerspace technologies are increasingly being explored as alternatives that have potential to enable anyone to fabricate microfluidic structures. We therefore tested simple fabrication methods for a PDMS-based microfluidic device. On the one hand, channels were replicated from capillaries and tape. On the other hand, different mold fabrication methods, namely laser cutting, fused layer 3D printing, stereolithographic 3D printing, and computer numerical control (CNC) milling, were validated in terms of machine accuracy and tightness. Most of these methods are already known, but the incorporation and retention of particles with sizes in the micrometer range have been less investigated. We therefore tested two different types of particles, which are actually common carriers for the immobilization of enzymes, so that the resulting reactor could ultimately be used as a microfluidic bioreactor. Furthermore, CNC milling provide the most reliable casting mold fabrication method. After some optimization steps with regard to manufacturing settings and post-processing polishing, the chips were tested for the retention of two different particle types (spherical and non-spherical particles). In this way, we successfully tested the obtained PDMS-based microfluidic chips for their potential applicability as (bio)reactors with enzyme immobilization carrier beads.

See the full publication: