Three new publications have been released.

"Cell-free protein synthesis with technical additives - expanding the parameter space of in vitro gene expression" in Beilstein Journal of Organic Chemistry

Tabea Bartsch and her co-authors investigate cell-free protein synthesis (CFPS) to better understand the physical and chemical properties of CFPS. The focus of the study was on the investigation of non-physiological conditions to expand the parameter space of CFPS. In this study, the properties of an Escherichia coli extract-based CFPS system are evaluated using ten different technical additives including organic solvents, polymers and salts to extend the parameter space. The results show that the CFPS system is very robust even under non-physiological conditions.

Here you can find the publication

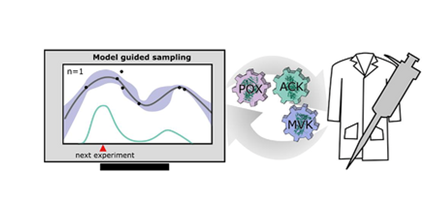

"Avoiding Replicates in Biocatalysis Experiments: Machine Learning for Enzyme Cascade Optimization" in ChemCatChem

Regine Siedentop and her co-authors develop an in vitro enzyme cascade for mevalonate phosphorylation and ATP regeneration using Bayesian optimization. The aim of the study was to optimize the new enzyme cascade for productivity and the productivity-cost ratio. The optimal compound concentrations were found in four iterations. In order to establish the optimal reaction conditions as efficiently and quickly as possible, the replicated experiments were deliberately avoided in the Bayesian optimization.

Here you can find the publication

"Ethanol production using Zymomonas mobilis and in situ extraction in a capillary microreactor" in Micromaschines

Julia Surkamp and her co-authors develop a new flow-through microreactor for the cultivation of the bacterium Zymomonas mobilis with simultaneous in situ extraction of ethanol as a product. The microreactor under consideration is a coiled flow inverter (CFI) consisting of a capillary wound on a support structure. The simplicity of the design makes the CFI particularly suitable for biochemical applications, as the cells cannot be trapped or damaged by internal structures. The reaction system consists of two phases, with the aqueous phase carrying the bacterium and an oleyl alcohol phase used to extract the ethanol produced. The results show the suitability of the CFI for the microbial production of valuable compounds.